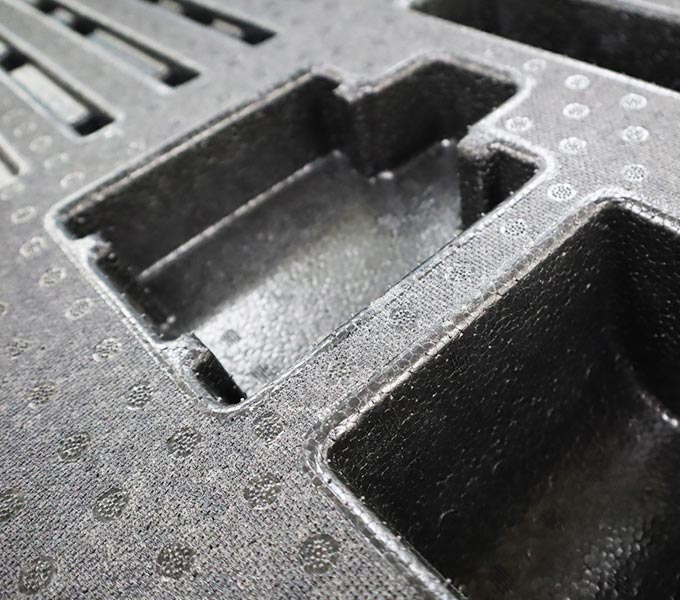

Since our founding in 1946, we have focused on the manufacture of styrene foam molds and have worked to improve the quality of these molds while introducing equipment such as large MC and casting machines. We will continue to challenge not only domestically but also to capture foreign demand by making the most of our long years of rich experience and achievements as a mold maker.

Based on our many years of experience and know-how in foam resin mold manufacturing, we provide comprehensive support from design to manufacturing and delivery. We provide efficient molding and high precision products by designing molds from the viewpoint of the customer (molding manufacturer). In particular, we manufacture a large number of surface design molds and high-precision molds, and can also provide a wide variety of products, including the manufacture of molds processed from castings and rolled materials.

Automobile parts, home appliance parts, packaging materials, cushioning materials, construction materials, container boxes, daily sundries, core materials, etc.

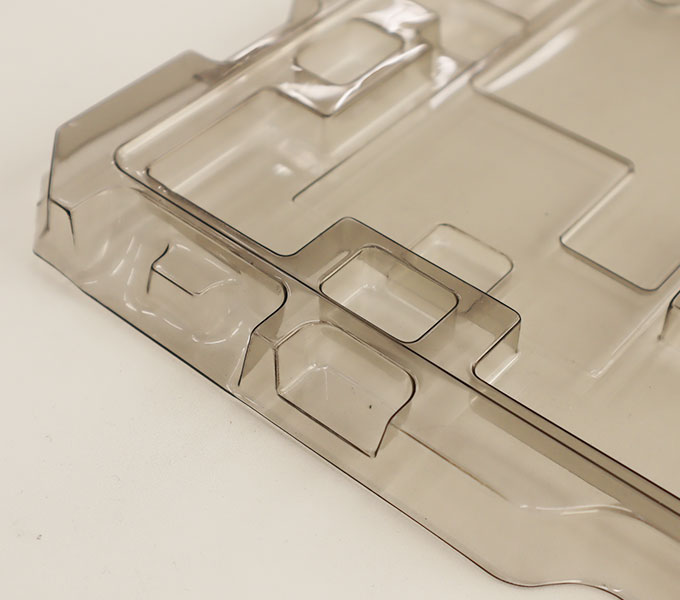

We can produce both aluminum molds (for mass production) and chemical wood molds (for prototyping), which are widely used in thermoforming. We design molds to meet customers' needs and provide products with short delivery times.

Automotive parts, automotive parts transportation trays, home appliance parts transportation trays, drain pans, product packaging, cosmetic cushioning materials, daily necessities, etc.

We can present prototypes designed from styrene foam (EPS), expanded polyprolylene foam (EPP), expanded polyethylene foam (EPE), chemical wood, and resin materials (acrylic, etc.) or machined from materials, allowing for low-cost confirmation prior to mold fabrication. We can also produce 3D data from illustrations of objects, event characters, and cosplay parts.

Automobile parts, home appliance parts, cushioning materials, packaging materials, container boxes, concrete formwork materials, objet d'art, parts for cosplay

We can design and manufacture jigs for product inspection and assist plugs for vacuum forming molds. We can also design 3D data for fitting to products and molds. We can also create highly accurate jigs and plugs by using optical measuring instruments to create data from actual products and molds.

Inspection jigs for automotive parts, inspection jigs for large building materials, jigs for crimping products, assist plugs for vacuum forming dies

We can produce the molds necessary for research and development. In order to research new technologies, it is necessary to propose the structure and design of molds and parts in an integrated manner to create something that does not yet "exist" while thinking together with our customers. We collaborate with universities and research institutes for development.

We provide training (acceptance system) to overseas die makers. We also receive requests for support in planning new overseas businesses and consulting for start-up factories, and we provide on-site guidance for the development of human resources for these projects. For students in Japan, we have a well-developed internship program and accept many students.